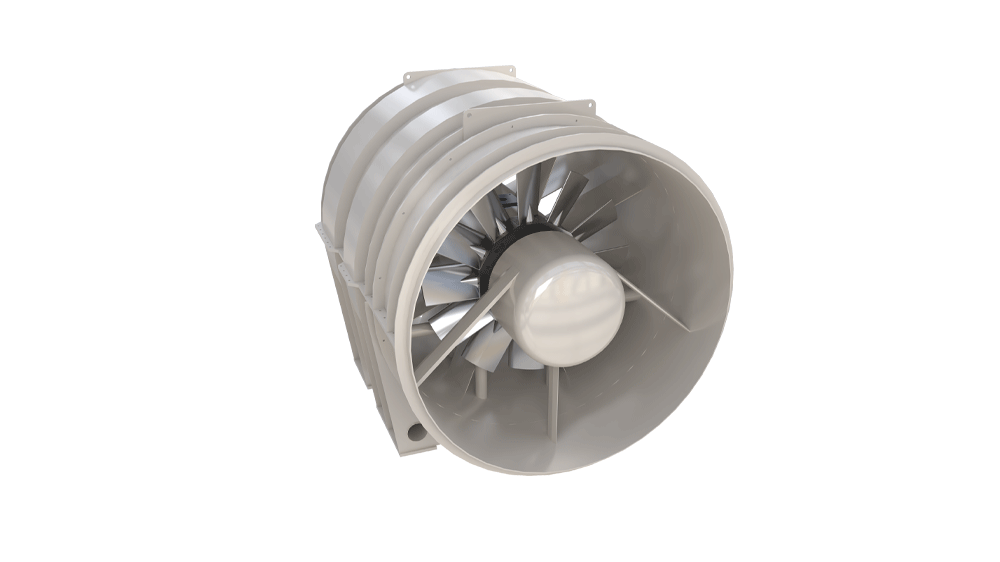

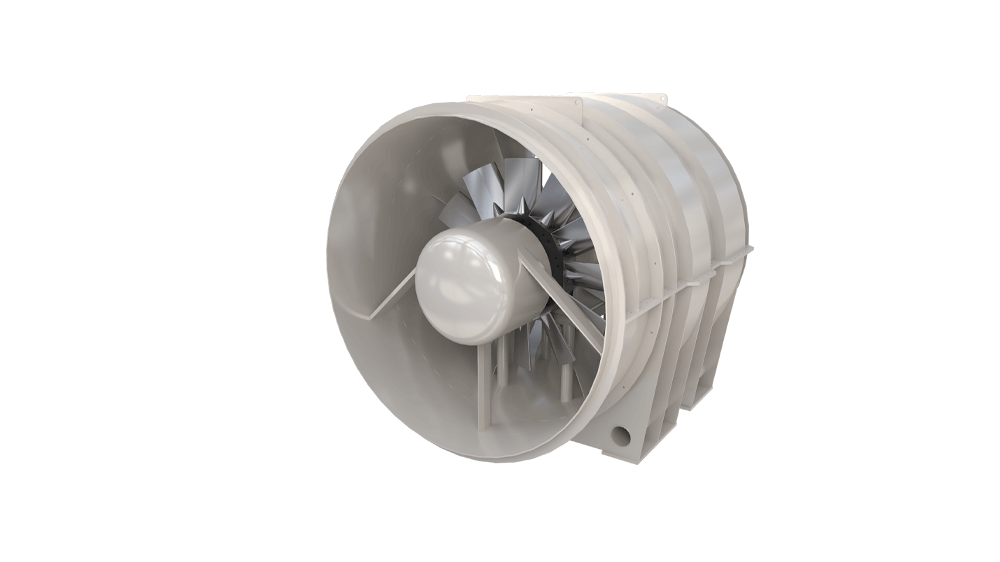

Model FA-DH

Axial Heavy Duty type-Fans

Performance Features

- Direct Connection: In these systems, the fan blade is directly connected to the electric motor.

- Blade Design: The fan blades for this type of fan are designed both as airfoil-shaped and unidirectional (Uni-directional airfoil) and bidirectional (Bi-directional).

- Airflow Capacity: The airflow capacity is up to approximately 500,000 cubic meters per hour.

- Static Pressure: The static pressure is up to approximately 3250 pascals.

- Blade Diameter: The diameter of the fan blade can reach up to approximately 3250 millimeters.

- Accessory Installation: There is the capability to install various accessories such as bird screens, base frames, and different types of dampers on these air movers.

- Main Usage: These fans are primarily designed and manufactured for ventilation purposes in metro stations, underground mining tunnels, and for the transportation of polluted air and gases that require a much higher airflow capacity.

- Vibration Balance: The vibration balance of these fans is based on the DIN ISO 1940-1 grade G 6.3 standard, with a vibration level of less than 4 mm/s.

Special Design Methods

- Corrosion Resistance: In environments with high corrosion and acidity, materials such as stainless steel 304 or stainless steel 316 are used for the body and fan blades of the fans. (stainless-steel Fans)

- Explosion & Spark Proof Fans: In environments where flammable gases and dust are present, fans are completely isolated from the surrounding environment to prevent sparks and explosions. Additionally, a layer of copper or composite insulation is used at the potential contact point between the fan blade and the fan body to prevent metal-to-metal contact. (Explosion & Spark Proof Fans)

- In Oil, Gas, and Petrochemical Industries: Axial fans are designed and manufactured according to international standards such as the API (American Petroleum Institute) and IPS-E-PR-755(1).