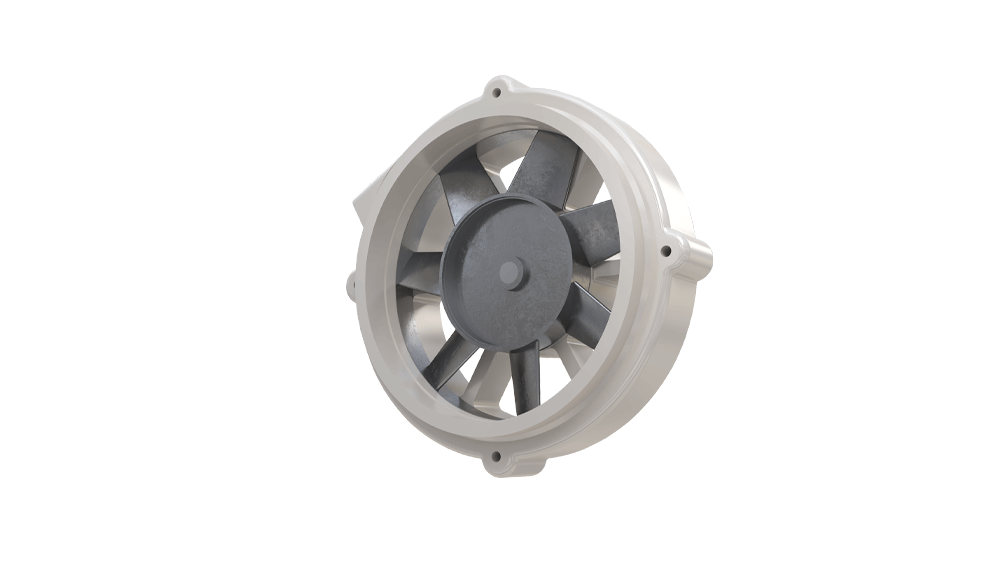

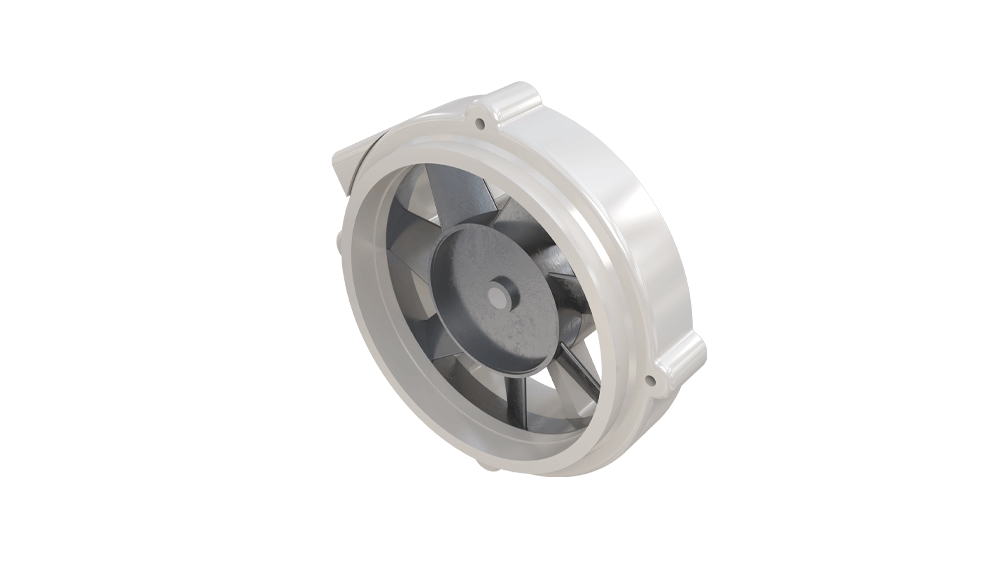

Model FA-PN

Axial Pneumatic-Fans

Performance Features

- In these systems, the fan blade is connected directly to the electric motor.

- The design of the fan blades for these types of fans is Uni-directional airfoil.

- The air delivery capacity is up to about 15,000 m3/hr.

- The static pressure is up to about 1500 Pascals.

- The diameter of the fan blades ranges from 300 to 500 millimeters.

- There is the capability to install various accessories, such as bird screens, base frames, and different types of dampers on these ventilators.

- These fans are primarily used in coal mines, where due to restrictions on the use of electrical equipment, air movement is achieved through compressed air.

- In general, the body and fan blades of these ventilators are made of cast aluminum. The vibration balance of these fans is according to the DIN ISO 1940-1 grade G 6.3 <4 mm/s standard.

Special Design Methods

- In environments with high corrosion and acidity, stainless-steel 304 or stainless-steel 316 is used for the body and impeller of the fans. (Stainless-steel Fans)

- In the presence of flammable gases and dust in the fan’s environment, to prevent sparks and explosions, the fan is fully isolated from its surroundings. Additionally, a layer of copper or composite insulation is applied to potential contact points between the impeller and the fan body. (Explosion & Spark-proof Fans)

- In the oil, gas, and petrochemical industries, axial fans are designed and manufactured according to the international API and IPS-E-PR-755(1) standards. Upon the client’s request and specific conditions, the fan impellers can be designed and manufactured to be symmetrical and bi-directional. (Bi-directional blades)