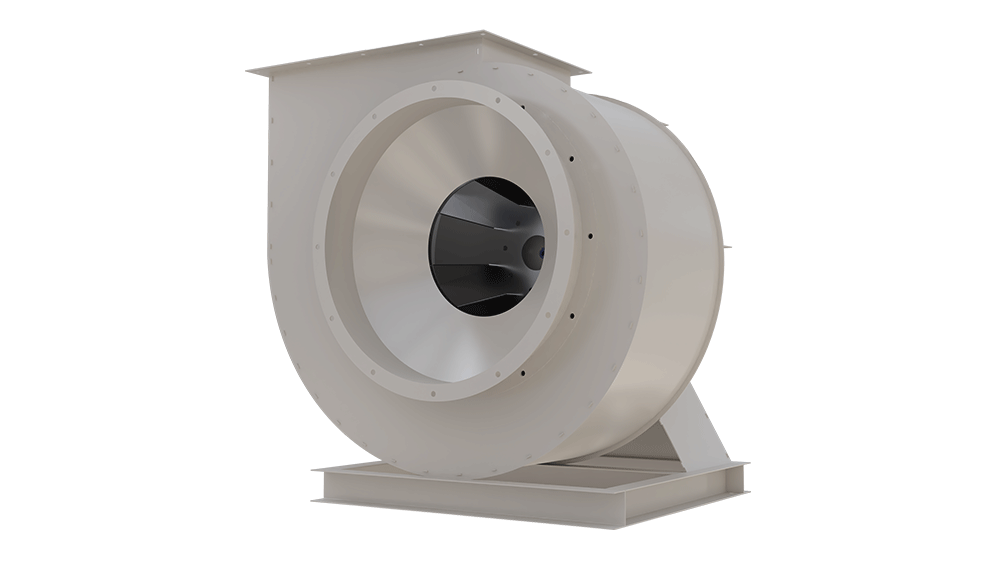

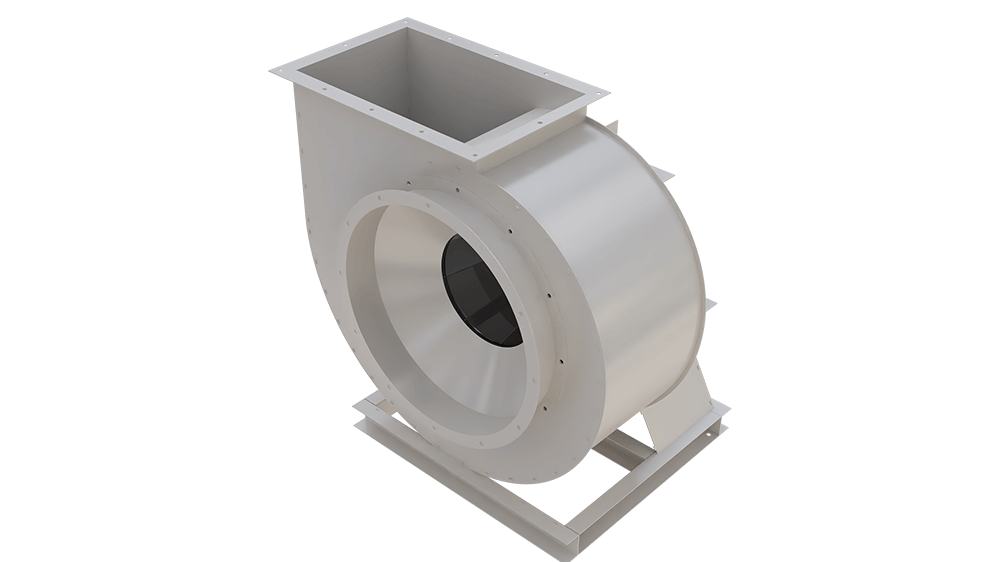

Model FC-BMDS

Single Inlet-Direct Drive

Performance Characteristics

- In these systems, the connection between the impeller and the electric motor is primarily direct, ensuring efficient power transmission and operational integrity. This direct linkage fosters seamless coordination, akin to a well-synchronized dance between components.

- The design philosophy of these fan types adheres to the Impeller Overhung method, as prescribed by the respected AMCA standards. This method provides a robust framework for engineering, akin to a blueprint guiding the construction of a sturdy bridge, ensuring reliability and adherence to industry benchmarks.

- These fans boast an impressive air handling capacity, capable of circulating up to 100,000 cubic meters of air per hour. This volume is akin to the air displacement of a large hot air balloon, illustrating the significant scale of airflow management achievable by these systems.

- With a static pressure capability reaching up to 5,000 pascals, these fans can effectively overcome resistance and maintain airflow even in challenging environments, comparable to a powerful river current navigating obstacles along its course.

- The diameter of the fan impeller extends up to 1250 millimeters, resembling the diameter of a large circular table, illustrating the substantial size and coverage area of these fan assemblies.

- These fans exhibit versatility in adapting to varying input airflows, facilitated by features like dampers and variable frequency speed control. This adaptability is akin to a chameleon seamlessly blending into different environments.

- Operating within a temperature range of -20 to 150 degrees Celsius, these fans demonstrate resilience in extreme conditions, akin to a seasoned explorer traversing diverse landscapes with ease.

- The positioning and angle of the outlet mouth relative to the inlet, conforming to AMCA standards, are customizable, akin to adjusting the angle of a spotlight to precisely illuminate a desired area.

- Furthermore, these fans accommodate the installation of various accessories such as dampers, bird screens, and frames, akin to customizing a vehicle with optional extras to enhance functionality and performance.

- Primarily deployed in gas and contaminated air collection and transportation systems, these fans play a pivotal role in maintaining air quality and safety standards, akin to the guardians safeguarding the purity of the air we breathe.

- Considering both capacity and operational efficiency, the fan blades can be designed as either backward curved or backward inclined, offering flexibility to suit specific performance requirements, akin to selecting the appropriate tool for a particular task.

- The vibration balance of these fans adheres to stringent ISO standards, ensuring smooth and stable operation, akin to the steady rhythm of a well-tuned orchestra performing in perfect harmony.

Special Design Methods

- In environments with high corrosion and acidity, materials like stainless steel 304 or stainless steel 316 are utilized for the body and impeller of the fans, ensuring durability and resistance to deterioration, akin to fortifying structures to withstand harsh conditions.

- In scenarios where flammable gases and dust are present, fans are fully isolated from the surrounding environment to prevent sparks and explosions. Additionally, an insulating layer of copper or composite material is applied to potential contact points between the impeller and fan body, ensuring safety and mitigating risks, akin to adding safety measures to prevent accidents in hazardous areas.

- Centrifugal fans in industries such as oil, gas, and petrochemicals are designed and manufactured according to international standards such as API 560 & API 673, ensuring compliance with industry regulations and specifications, akin to adhering to established protocols to maintain quality and reliability.