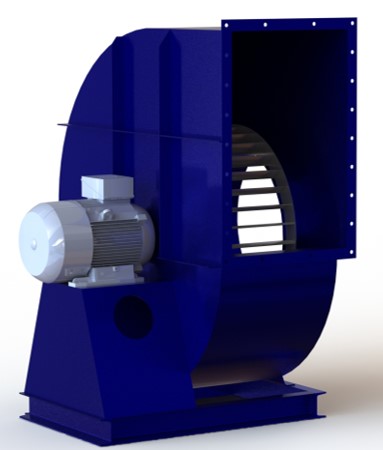

Model FC-FLDS

Single Inlet-Direct Drive

Performance Characteristics

- In these systems, the connection of the impeller to the motor is indirectly and via belt drive.

- The design of these types of fans is based on the impeller method, both between two bearings (Impeller Between Bearing) and also (Impeller Overhung), according to the AMCA standard.

- The air handling capacity is up to approximately 150,000 cubic meters per hour.

- The static pressure is up to about 700 pascals.

- The diameter of the fan impeller reaches up to 1000 millimeters.

- The inlet air volume can be adjusted using a damper or by changing the speed frequency.

- These series of fans can have suitable performance within a working temperature range of -40 to 500 degrees Celsius.

- The position of the outlet mouth relative to the inlet and its angle relative to the horizon can be selected according to the AMCA standard.

- The ability to install any accessories such as damper, silencer, bird screen, chassis, etc., on these air handlers exists.

- The vibration balance of these fans is according to the ISO standard DIN ISO 1940-1 grade G 6.3 <4 mm/s.

Special Design Methods

- In environments with high corrosion and acidity, stainless-steel 304 or stainless-steel 316 materials are used for the body and impeller of the fans (stainless-steel fans).

- In the presence of flammable gases and dust in the environment where the fan is located, to prevent sparks and explosions, the fan is completely isolated from the surrounding environment. Additionally, a layer of copper or composite insulation is used on the potential collision area between the two-metal impeller and fan body (Explosion & Spark proof Fans).

- In the oil, gas, and petrochemical industries, centrifugal fans are designed and manufactured according to the international standards API 560 & API 673.