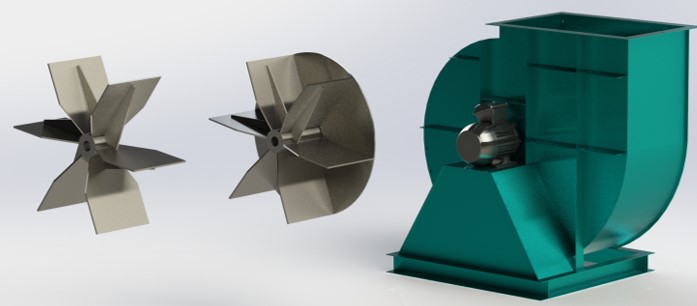

Model FC-RD

Radial-type Fans

Performance Characteristics

- In these systems, the fan blade is connected to the electric motor indirectly using a pulley-belt mechanism.

- The design of these fans is based on the methods “Impeller Between Bearing” and “Impeller Overhung” according to the AMCA standard.

- The air flow capacity is up to approximately 360,000 cubic meters per hour.

- The static pressure is up to approximately 5,000 Pascals.

- The fan blade diameter can reach up to 1600 millimeters.

- The incoming air flow can be adjusted with a damper or by changing the frequency of the speed.

- These fans can operate effectively in a temperature range of -40 to 500 degrees Celsius.

- The position of the outlet relative to the inlet and its angle to the horizontal can be selected based on the AMCA standard.

- It is possible to install various accessories such as dampers, silencers, bird screens, and frames on these fans.

- Most of these fans are used in systems for collecting and transferring gases and polluted air.

- Based on the capacity and performance efficiency, the fan blades can be designed as either backward curved or backward inclined.

- The vibration balance of these fans is according to the DIN ISO 1940-1 grade G 6.3 standard, with a vibration level of less than 4 mm/s.

Special Design Methods

- In environments with high corrosion and acidity, materials such as stainless steel 304 or stainless steel 316 are used for the body and fan blades (stainless-steel fans).

- If there are flammable gases and dust in the environment where the fan is located, to prevent sparks and explosions, the fan is completely isolated from the surrounding environment. Additionally, a layer of copper or composite insulation is used at potential contact points between the fan blade and the body (explosion and spark proof fans).

- In the oil, gas, and petrochemical industries, centrifugal fans are designed and manufactured according to the international oil standards API 560 and API 673.